#### Introduction

ePaper (electronic paper) technology shines in display quality, energy efficiency, and design innovation. In recent years, ePaper products have exploded in variety, launching new applications annually across IoT and consumer electronics. Scheduled for August 28th, the ePIC 2025 Second Electronic Paper Industry Conference in Shenzhen will highlight these innovations. The Electronic Paper Industry Alliance (EPIA) and Qudrant Lab will share stories of groundbreaking ePaper applications, decoding new products to drive technology and inject momentum into emerging display and IoT fields.

ePaper redefines human-screen interaction with core perks: paper-like eye protection and ultra-low power use. Its low energy consumption, long battery life, and recyclability aren’t just tech advancements—they're a promise to a sustainable future, where less energy creates lasting value and blends eco-friendliness with innovation.

From reading comfort to dynamic display magic, every ePaper use breaks traditional display limits. Whether as real-time price tags in smart retail, eye-friendly tablets in education, or smart decor in buildings, ePaper's flexible forms blend tech into life, fueling industry upgrades.

#### The Key Material Behind the Scenes: Conductive Silver Paste

##### 1. Spotting the Need, Taking on the Challenge

Years back, as ePaper boomed, a problem emerged: traditional conductive materials had major flaws. Some conductive pastes had high resistance, slowing signal transmission and messing up display smoothness. Solvent-based silver pastes released VOCs, harming the environment and workers. They also had weak adhesion, failing to stick to ePaper’s various substrates—loosening during temperature changes or vibrations, causing unstable connections. Thermoset pastes cured too slowly, needing high heat and long time, killing production efficiency for mass ePaper manufacturing.

The R&D team at Weijing Technology saw this industry pain point. Talking with ePaper makers, they realized a UV-curable conductive silver paste made for ePaper could solve these issues and power ePaper’s growth. So, the mission to develop ePaper-specific UV conductive silver paste began.

##### 2. Overcoming Hurdles, Cracking the Code

At the start, the team faced big challenges. First, balancing conductivity and flexibility. They tested silver powder size, shape, and distribution endlessly. They sourced high-purity silver powder from different suppliers, nano-ground and treated it to improve dispersion in the paste. After tons of trials, they found a unique silver powder formula—super low resistance and flexible enough for bendy ePaper.

Next, they focused on adhesion. ePaper uses plastics, glass, metal—all with different surfaces. The UV paste needed to stick to them all. The team studied surface chemistry and developed a new coupling agent system—a "bridge" bonding the paste to substrates. Tests showed it stayed stuck through bending and vibration, no peeling.

For UV curing, traditional pastes had issues—undercuring, sticky surfaces, messing up quality and speed. The team designed a new photoinitiator system that cures fast under specific UV light. Optimizing curing parameters (light intensity, time, temp) ensured consistent curing in any production setting, boosting efficiency and quality.

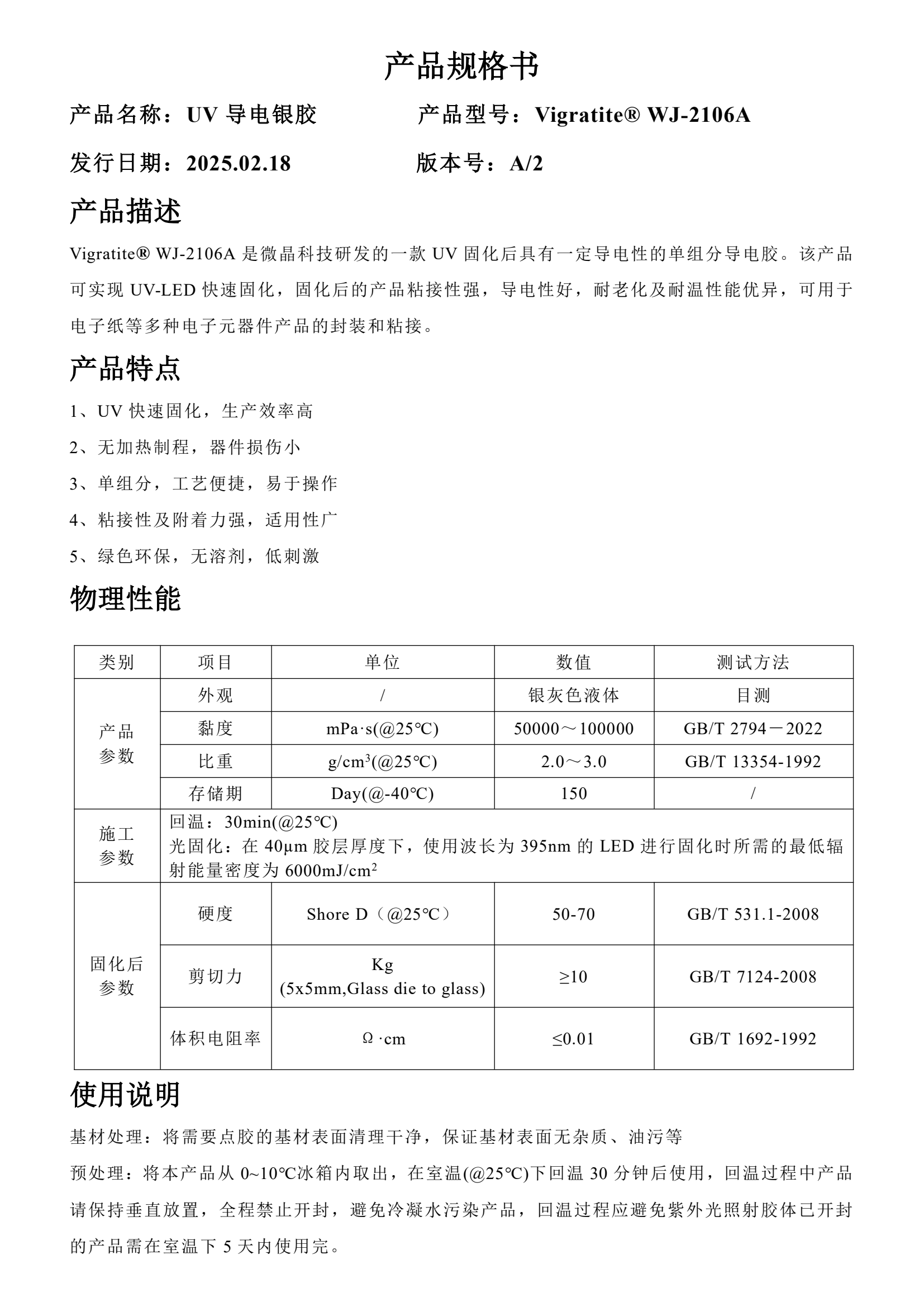

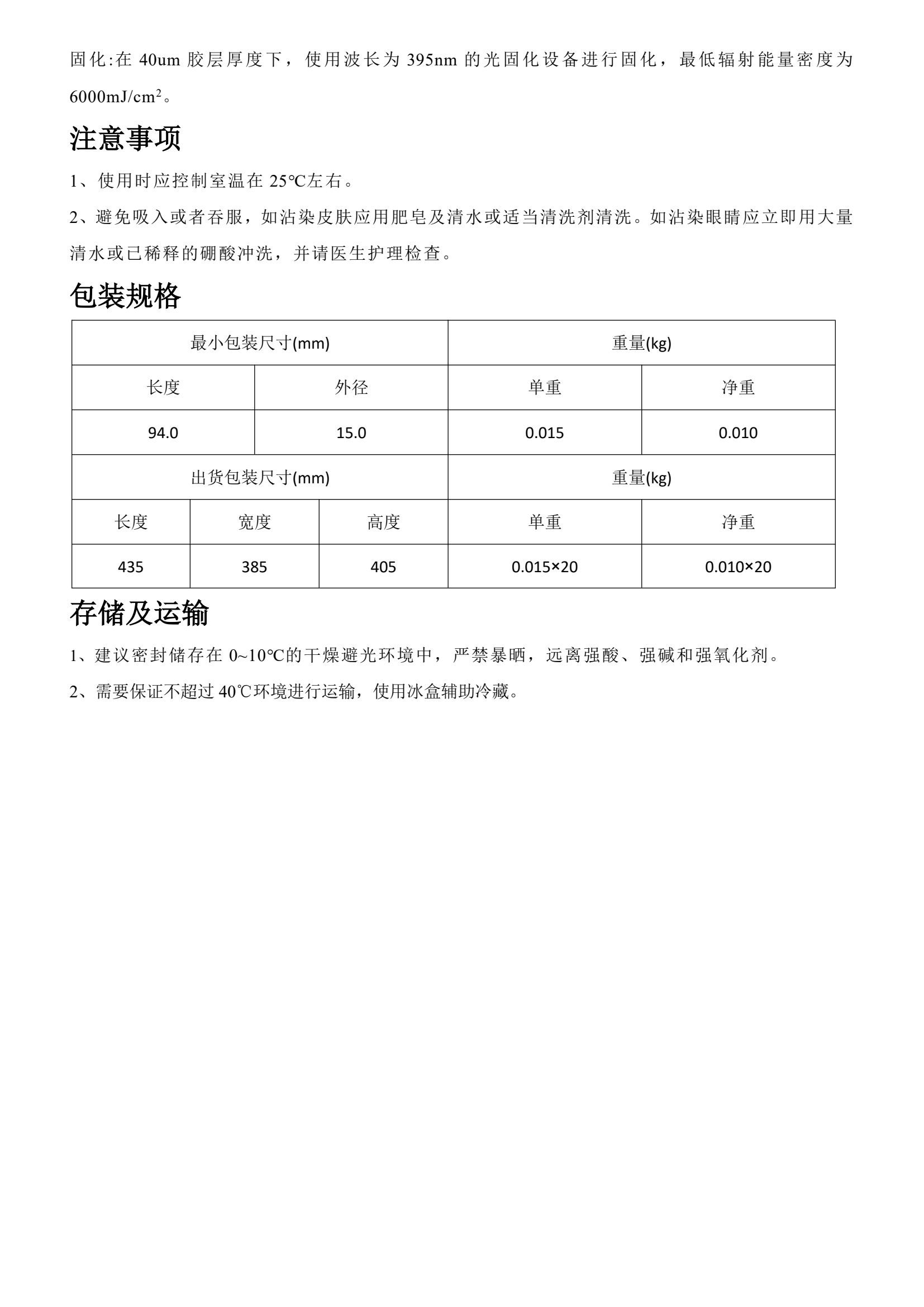

##### 3. The Game-Changing Product: WJ-2106A

After non-stop R&D, Weijing Technology launched WJ-2106A—UV conductive silver paste for ePaper.

- **Ultra-low resistance**: Way lower than competitors, enabling efficient power transmission for quick, stable ePaper displays.

- **Super flexibility**: Survives tens of thousands of bends, keeping conductivity and structure—perfect for flexible ePaper.

- **Strong adhesion**: Sticks to any substrate—plastic, metal, etc.—no more equipment failures from peeling.

- **Fast UV curing**: Cures in a flash, cutting production time, raising efficiency, and lowering defects.

- **Eco-friendly**: No harmful solvents, meeting modern green manufacturing standards.

##### 4. Driving the Industry Forward

WJ-2106A brings huge opportunities to ePaper: used in e-readers, smart logistics labels, wearables, commercial signs—even expanding to smart agriculture, healthcare, and homes as ePaper grows. It supports smaller, thinner, higher-performance ePaper devices, upgrading the whole supply chain.

Weijing isn't stopping here. Starting with WJ-2106A, they’re researching how to cut costs for mass use and add functions like waterproofing, heat resistance for tough environments.

On the path of ePaper UV conductive silver paste innovation, the company will keep leading with tech and products, shaping the industry's future. Soon, ePaper will play a bigger role in our lives, and WJ-2106A—along with future innovations—will be the vital link, shining with tech and creativity, coloring our digital world.