An ePaper screen that can bend around objects is quietly reshaping our perception of screen forms, starting with cryptocurrency wallets.

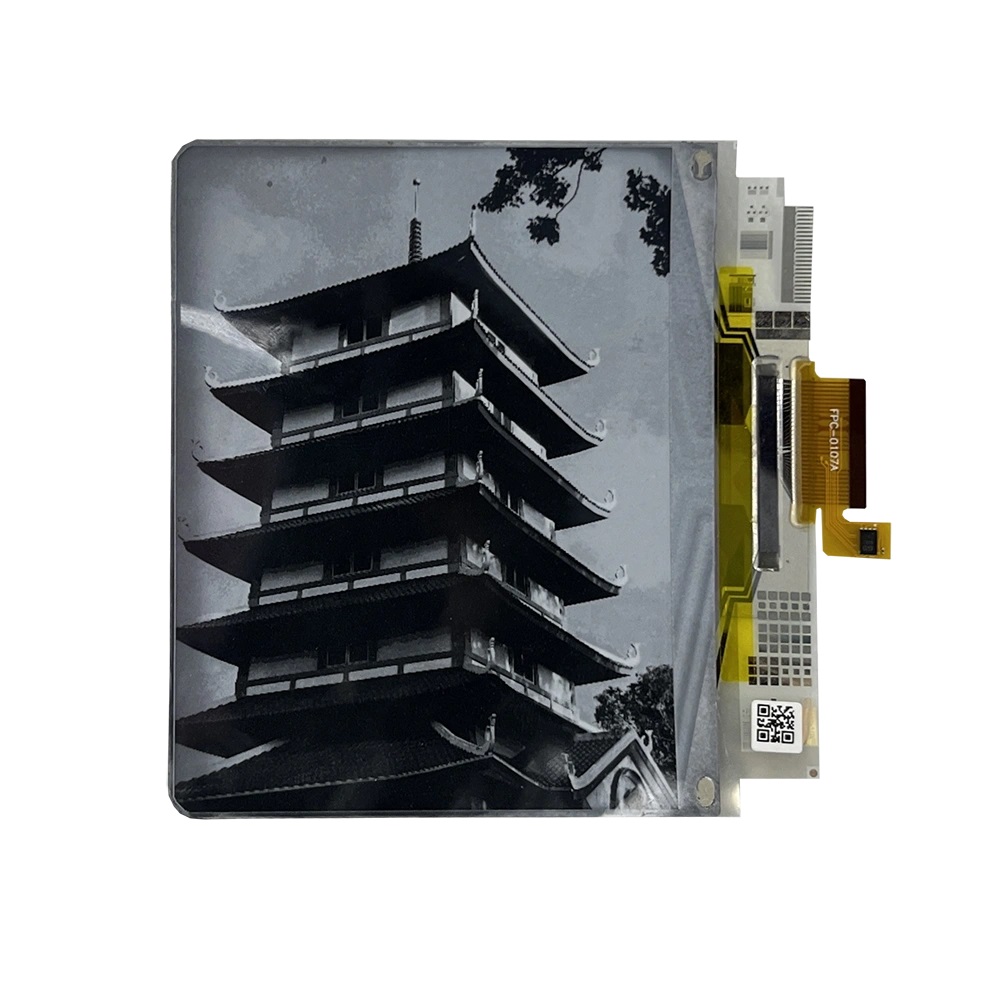

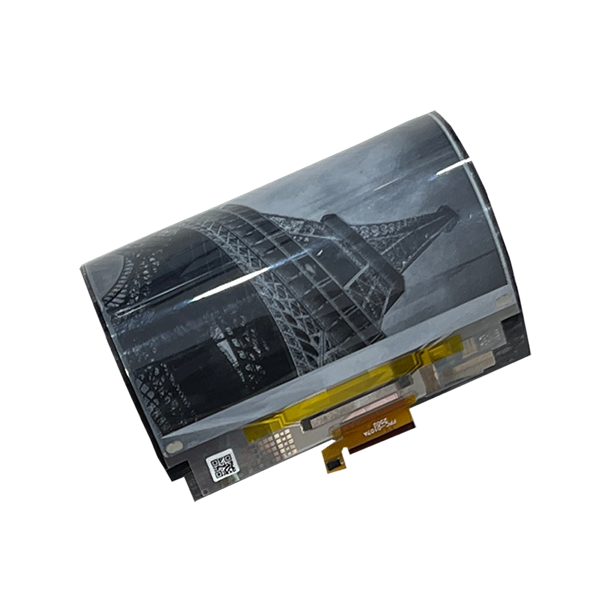

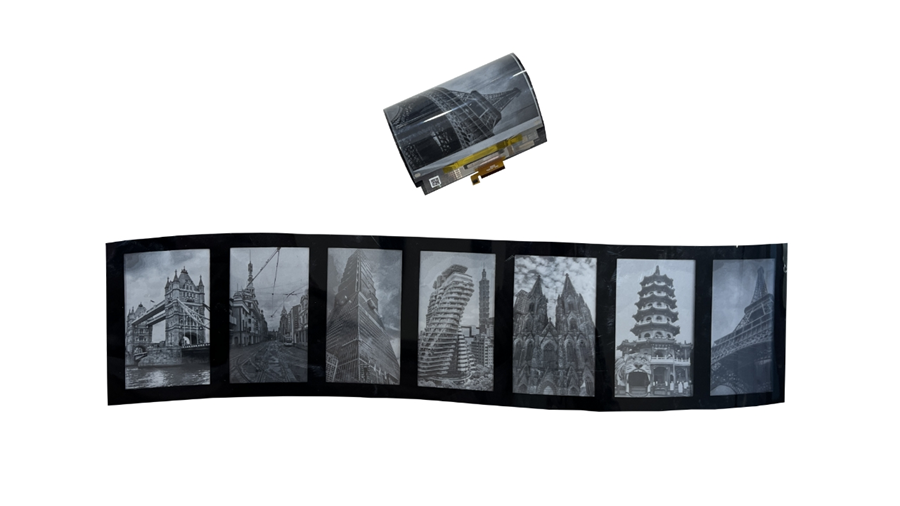

On Ledger Stax, the latest creation from the French hardware crypto wallet manufacturer, an e-ink screen capable of 180° wraparound bending has become the core of the product’s design. This credit card-sized display bends and fits flexibly, achieving an unprecedented curvature radius that allows users to access content from the wallet’s side edges.

But what truly stands out is the technological revolution behind this elegant design—it marks the world’s first mass-produced consumer electronics product using Organic Thin-Film Transistor (OTFT) technology.

### Technological Breakthroughs: The "Triple Revolution" of Flexible OTFT

#### Material Revolution: From Silicon-Based to Organic Polymers

Traditional ePaper relies on silicon-based transistors and glass substrates, suffering from rigidity, fragility, excessive thickness, and high energy consumption. DKE’s flexible screen adopts FlexEnable’s organic polymer material, FlexiOM™, replacing glass with plastic substrates (e.g., PEN). This reduces thickness by 80% while enabling 180° bending and shatter resistance. Organic polymers allow electronic components to be directly formed on ultra-thin plastic, breaking the physical limitations of silicon-based materials and laying the foundation for curved displays.

#### Process Innovation: Low-Temperature Manufacturing and Structural Overhaul

- The manufacturing temperature has dropped from 350°C to below 100°C, cutting energy consumption by 70%.

- DKE developed the world’s first 180° bending lamination process, solving the problem of circuit integrity under extreme bending and ensuring uniform display quality.

- Structurally, it adopts an "all-plastic architecture" (PEN flexible substrate + FPL ePaper film), replacing traditional etched TFT hard boards and integrating "flexible bending + touch functionality" into one.

#### Performance Leap: Redefining ePaper Boundaries

Ultra-low power consumption: Equipped with Eink’s ePaper display film, the screen features bistable properties (users can customize personalized images in shutdown or standby mode), consuming only 1/1000th of the power of traditional solutions.

### Challenges from Lab to Million-Scale Production

#### The Battle for Yield in 180° Bending Lamination

Extreme bending significantly increases the risk of circuit breakage. DKE addressed this by developing precision multi-layer film lamination technology and flexible circuit compensation designs, dispersing stress in the bending area and raising mass production yields to a commercially viable level.

#### Vertical Supply Chain Integration

Since establishing its flexible ePaper R&D team in 2022, DKE has collaborated with material suppliers and equipment manufacturers to build a closed-loop supply chain, shortening the cycle for technology commercialization.

### From Crypto Wallets to a Billion-Scale Market

**Debut Scenario: Ledger Stax Crypto Wallet**

As the world’s first OTFT consumer electronics product, its "wraparound screen" design redefines the interaction experience of hardware wallets, becoming a landmark case for flexible electronics commercialization.

**Technology Spillover: Unleashing Cross-Industry Applications**

| Application Field | Core Scenarios | Technical Adaptability |

|-------------------------|-----------------------------------------|------------------------------------------------|

| Consumer Electronics | Foldable devices, e-books, notebooks | Ultra-thin flexibility + low-power driving |

| Wearable Devices | Smart watches, fitness bands, medical wearables | Temperature resistance, vibration resistance + curved fitting |

| Industrial & Logistics | Industrial control interfaces, flexible industrial labels | Physical impact resistance + thin, low-power |

| Automotive Electronics | Seamless integration into streamlined interiors (displaying vehicle status or entertainment info) | Flexible fitting + glass-free safety |

**"Made in China" Paradigm for Flexible Electronics**

DKE’s 3.9-inch OTFT screen is not just a technological leap but also an innovation model of "international IP + local manufacturing + scenario implementation":

1. **Terminal demand drives technological iteration**: Ledger’s demand for "extreme curvature + ultra-low power consumption" pushed DKE to break process limits.

2. **Balancing patents and mass production capabilities**: FlexEnable’s 550 patents were transformed into tangible products through DKE’s process know-how.

3. **Green manufacturing DNA**: Low-temperature processes and bio-based materials offer a low-carbon path for the electronics industry, aligning with global sustainability goals.

The story of DKE’s flexible screen began with a curved crypto wallet display but points to a future where "displays are everywhere." When screens can seamlessly wrap around wrists, car windows, or even clothing, information carriers will break free from rigid constraints. This shift will profoundly impact consumer electronics, automotive electronics, augmented reality, and more, ushering in a new era of human-machine interaction. The key to this revolution lies in the material shift from silicon to organic polymers—flexible light will ultimately illuminate every corner of the Internet of Everything.