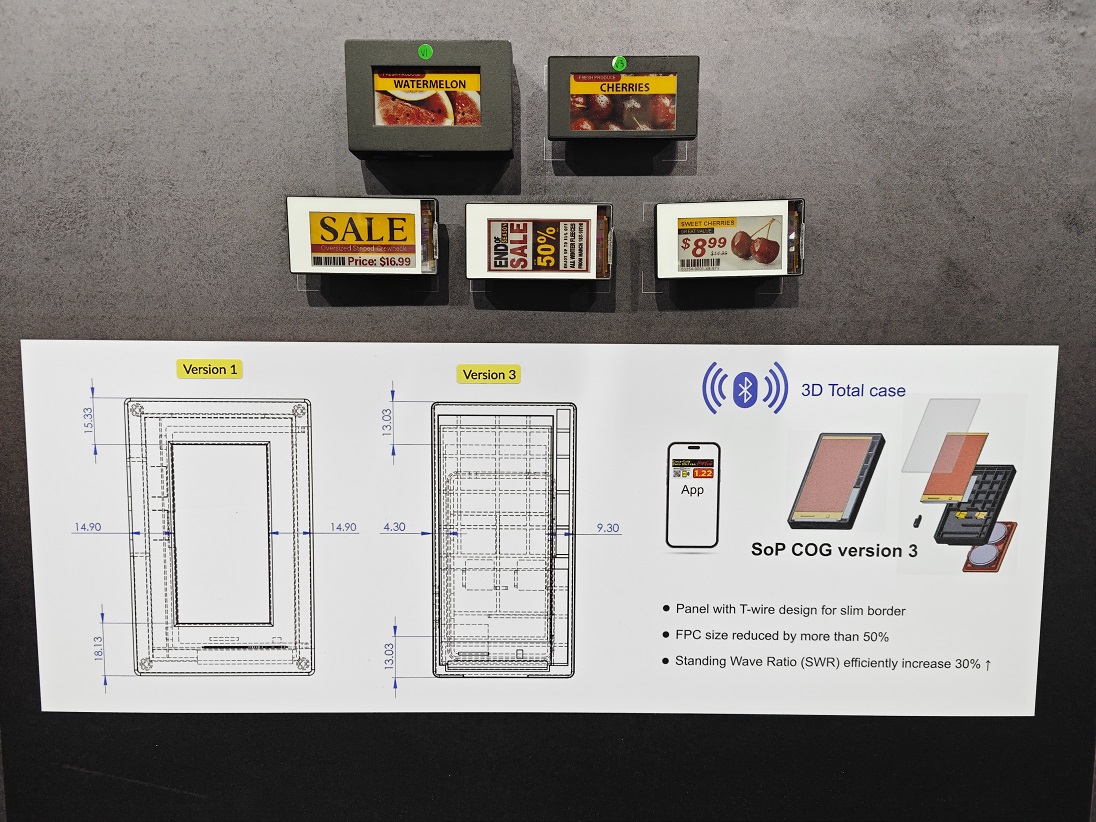

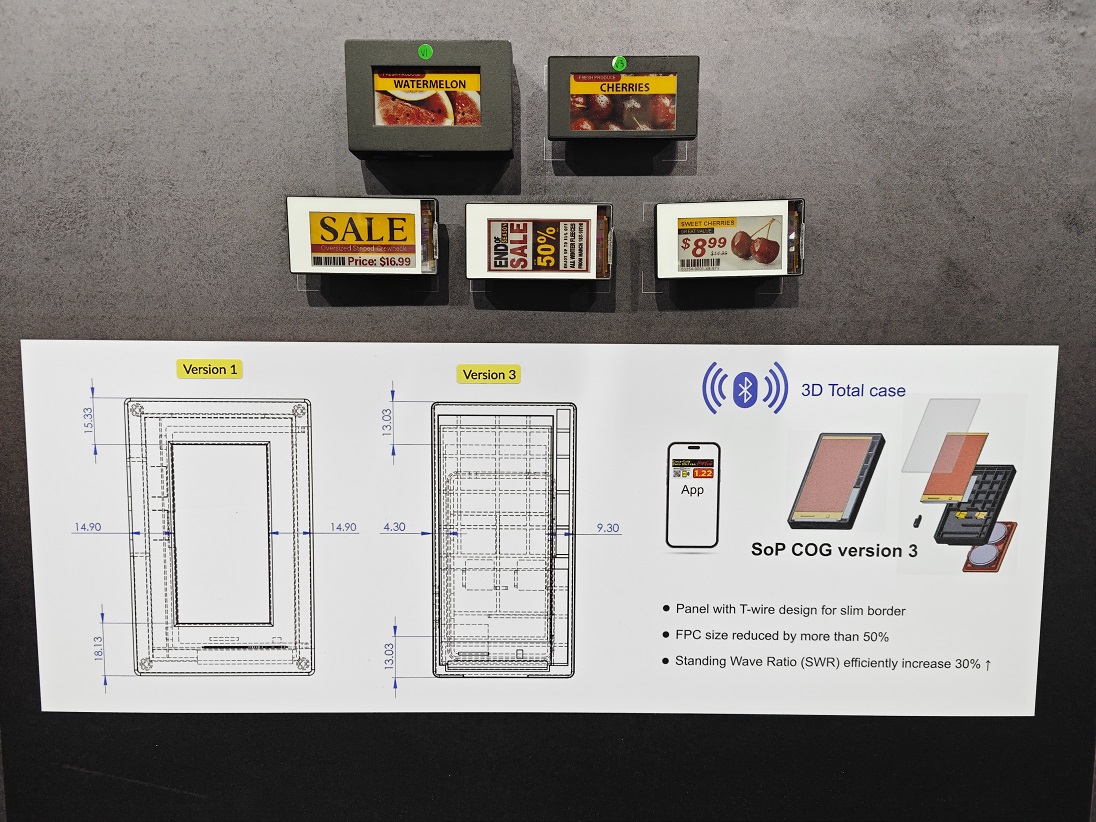

"Integrating RF functionality into glass panels could let 'Panle ePaper shelf labels' break free from rigid boards, shrink in size, simplify assembly, and cut costs—interested?" This question kicked off their collaboration. Two years later, in spring 2025 at Touch Taiwan, the first technical flower of their "Blue Ink Duet" bloomed, heralding a vibrant future for ePaper product design.

Thermal Stress: Circuit packaging temperature difference controlled within ±5°C.

RF Noise: Solved 2.4GHz band noise spikes from ePaper's high-voltage driving scans.

Thickness Threshold: Total stacking thickness <220 microns to pass 100,000 bend cycles.

30% reduction in TFT area, 50% smaller FPC; world’s first RFIC directly embedded in glass.

2.66-inch ESL (Electronic Shelf Label) standby current <1.56 microamps.

Technical Leap: SoP on ePaper panels optimizes circuit layout and transmission lines, matching traditional labels' signal range for commercial use. FPC stacking on the panel back reduces size and material consumption, aligning with ESG sustainability.

Industrial Value: As an ePaper leader, E Ink aims for net-zero carbon by 2040. Realtek’s redistribution layer technology integrates RF chips into 2.66-inch ePaper glass substrates, replacing traditional wire bonding to enable deep semiconductor-display integration for next-gen retail products.

Ecosystem Expansion: As a global Bluetooth platform leader, Realtek offers low-power, high-integration, multi-protocol wireless solutions with a complete development ecosystem, upgrading Bluetooth from a connection tech to a scenario gateway. The partnership extends "wireless neural networks" to shelves, wearables, smart homes, etc.

A 3-inch ePaper label: With ~600 million installed globally over 7 years, daily 4x price updates see paper labels emit 32,000x more CO₂ than ePaper.

30 million 10-inch ePaper ad screens used for 5 years: LCDs emit 12,000x more carbon, and printed materials 60,000x more than ePaper.

SoP+COG technology reduces plastic use by 18g per label by integrating glass, IC, and FPC, eliminating extra plastic frames and connectors.

Mass Production Ready: Realtek and E Ink released the 2nd-Gen SoP-ESL reference design in March 2025, cutting TFT area by 30% and FPC by 50% to lower costs.

Carbon Neutrality Drive: European and American retailers have set 2026-2028 as ESG transition key years, with SoP’s integrated structure aligning with market demand for carbon reduction.

Scenario Expansion: From shelves to smart logistics (COG modules on reusable pallets for real-time temperature/humidity reporting), and from stores to hotel conferences (ultra-thin, wireless, OTA-upgradable custom signages).

Market Implementation: Leading retailers are finalizing label replacement plans. The Realtek × E Ink SoP+COG technology has moved from tech demonstration to market-driven adoption, with 2026 set as the first global mass production year.