## I. Project Overview

The electronic ink screen of electronic price tags is a product that has catered to the market's concept of low power consumption, green environmental protection, and energy conservation in recent years. The electronic paper inside the ink screen of electronic labels consists of microcapsules made of solvents, which require a specially formulated edge-sealing epoxy adhesive to protect the displayed electronic paper. The adhesive needs to have basic properties such as good fluidity and wettability, a long service life, and high bonding strength to glass and PS films. At the same time, it must have ultra-long 45-day resistance to high temperature and high humidity, high temperature and dry heat, and high and low temperature impact. Due to the long-term supply by overseas brands with high prices and poor service, the customer hopes to develop a domestic product with price advantages. In addition, the aging resistance period is required to be longer, up to 50 days.

Figure 1 Application Picture

## II. Main Research Work Completed in the Project

### 2.1 Project Implementation Progress

1. August-September 2023: Wrote Stage Gate (concept submission form), technical service report, DFMEA, project initiation report, etc., clarified the division of labor among project team members, and discussed raw material selection according to various performance requirements.

2. October-December 2023: Formulated specific performance characterization plans; designed initial formulas according to predetermined technical indicators, conducted testing and analysis; adjusted formulas, continued to screen the types of main raw materials, and explored the preparation process of formula samples; during the testing and analysis of formula samples, it was found that the WVTR (water vapor transmission rate) was relatively high, and the product modulus was relatively high, resulting in failure under cold and heat shock. Further experiments were conducted to analyze the problems; sent formula samples to customers for testing.

3. January-March 2024: Sent sample ES028. The customer reported that for the black and white screen, there was slight edge damage after 45-day reliability test, and the customer agreed to further test on the black and white screen project. The R&D team readjusted the formula and sent a new product ES028W2 to the customer for testing. The customer reported that the display of the 13-inch product under 60°C-80% condition was slightly poor; the differences in other products were not obvious when confirmed in parallel; the number of reliable days was based on the customer's recorded feedback, which could not be verified on site. Physical observation showed that our product was basically the same as 7301N, but there were slight differences compared with Youbai (YB).

4. April-June 2024: The R&D team further adjusted the formula. ES28284 had the best comprehensive performance, which was close to that of the competitor 7301n. ES28283 and ES28282 were slightly worse, not as good as YB7300B-2. ES28284 had good fluidity, which caused glue shortage at the corners, but there were no bubbles this time. Therefore, it is necessary to confirm whether the filler content is too low. A total of 540 pieces were produced, with 6 defective pieces: 3 pieces with impurities, 1 piece with bubbles, and 2 pieces with glue shortage. At the same time, the client was verifying the processability, waiting for the client's verification result for the next step.

5. July-August 2024: The client's verification result was OK, and our company entered the pilot production stage in the large釜. No abnormalities were reported after 3 trial productions.

### 2.2 Project Technical Scheme

#### 2.21 Technical Implementation Plan

Adhesive formula design technology: Design and optimize the adhesive formula, including the selection of raw material types and proportions, to ensure that the adhesive has good bonding strength while ensuring its chemical resistance.

Process and equipment technology: Improve the testing or production equipment by optimizing the technical scheme of the formula sample preparation stage or testing stage to ensure the stability and reliability of the basic physical properties of samples or products in different batches.

#### 2.22 Key Technologies and Solved Problems

1. The developed one-component epoxy adhesive has both low curing temperature and fast curing speed, which fundamentally controls the negative impact of high temperature on electronic ink.

2. Improved the water resistance of the adhesive. The high barrier performance better protects the inside of the electronic ink capsules, avoiding the phenomenon that the characters displayed on the screen turn white or black due to the influence of water vapor.

3. The adhesive has good flexibility and excellent bonding strength to both soft plastic substrates and hard glass substrates.

4. Low viscosity, good fluidity at room temperature, and long operation time, suitable for automated production lines of screens of different sizes.

5. Excellent performance in the comprehensive reliability test of customer products (such as high and low temperature reliability, warpage, bonding strength, barrier performance, etc.).

6. Complies with environmental protection test requirements such as RoHS, low halogen, and Reach.

Innovation Points:

1. The one-component epoxy adhesive has both low curing temperature (such as 65°C, 70°C) and long operation time (>4hr).

2. Studied and improved the curable performance, flexibility, water resistance, and adhesiveness one by one, then balanced and optimized the comprehensive performance. At present, the elongation at break of high flexibility products is >100%; the WVPC (water vapor permeability coefficient) of low water permeability products under 50°C/100RH is <10gm·mil/[100inch²·day]; the bonding performance DSS (die shear strength) is >20kg (25°C, 3mm*3mm Glass/PET).

### 2.3 Phased Achievements

#### 2.31 Expected Goals (Technical Indicators)

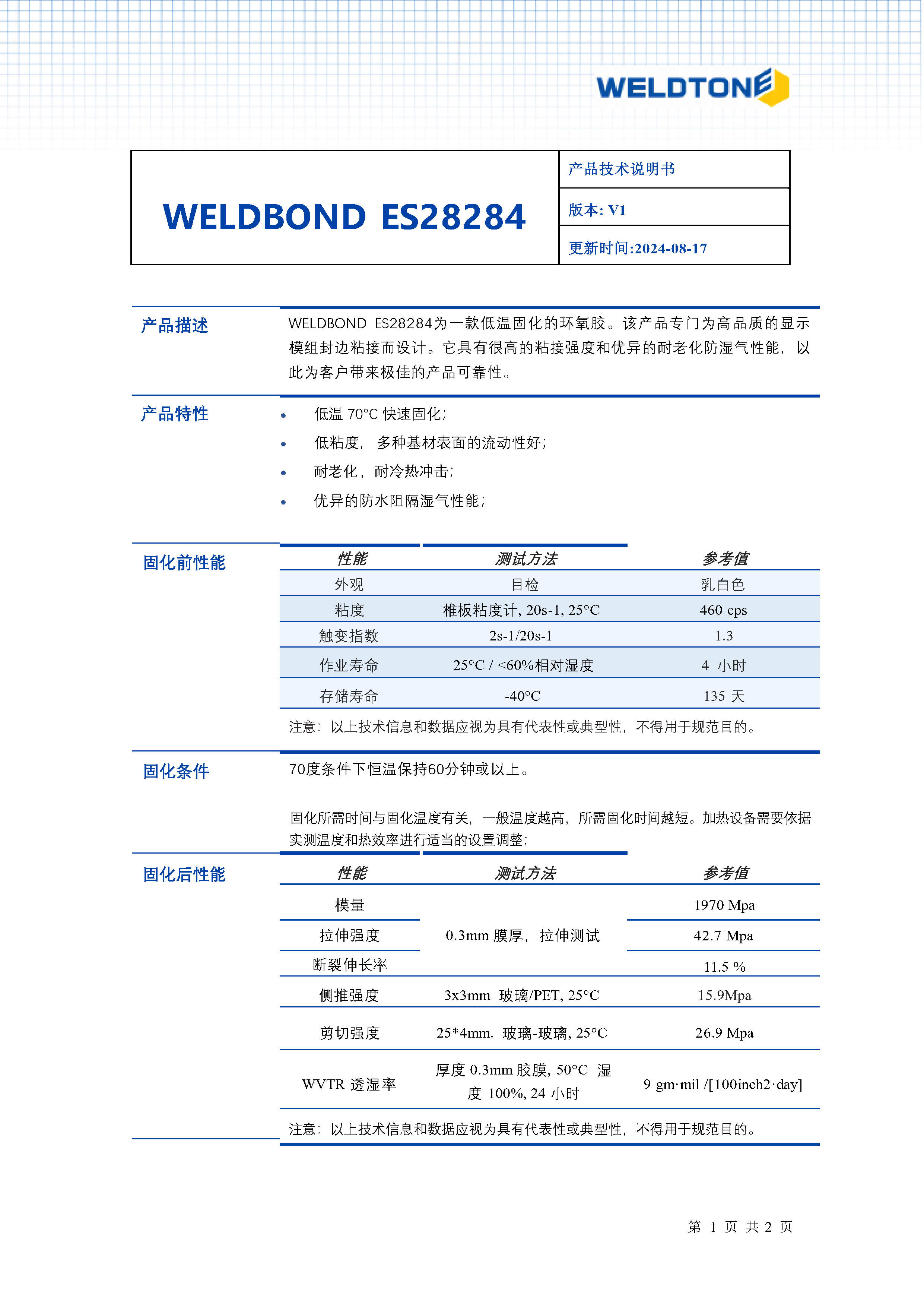

Main technical requirements: Viscosity 400-800; no bubbles during dispensing, good fluidity, flow distance >35mm in 10 minutes; curing at 70°C for 60 minutes, no yellowing, cracking, delamination, or bubbles after curing; modulus 1300-200MPa; shear strength on glass and PS film surfaces >6MPa; under specified environments, after 50 days of high temperature and high humidity, high temperature and low humidity, and cold and heat shock, the characters and patterns on the display screen have no abnormal display phenomena such as blackening or whitening, and no delamination or cracks.

#### 2.32 Report on Phased Achievements

1. The product cured at 70°C for 60 minutes meets the extremely strict 45-day reliability requirements of the client, including high temperature and high humidity, high temperature and low humidity, and cold and heat shock tests.

(Such as 65°C/85RH% >500H, 60°C/40RH% >45 days, (-40°C~60°C)/30min/cycle / 500cycles, 70°C storage time >500H, -40°C storage time >500H)

2. The low-temperature curing and high flexibility product for higher-end display applications has passed the preliminary test at the client's side and has begun to be gradually mass-produced. It is expected to complete mass production in the third quarter.

## III. Patent Situation

Patent application for the core technology of this project:

1. A low-temperature curing agent for epoxy resin and its preparation method, Acceptance No.: CN202210386289.X

## IV. Company Profile

WELDTONE Technology Co., Ltd. was founded in 2016, with its headquarters in Xiamen. It is a technology-driven enterprise focusing on high-end adhesives. Our innovative product lines cover multiple markets such as semiconductors, consumer electronics, and new energy. The company regards compound talents as its core competitiveness, with R&D personnel accounting for more than 30%. It has successfully developed and safely produced hundreds of adhesive products. WELDTONE has won nearly 100 honors such as "National Technology Innovation Demonstration Enterprise" awarded by the Ministry of Industry and Information Technology and "National High-Tech Enterprise". We are determined to become a global leader in adhesive technology, helping the global manufacturing industry with continuously innovative R&D solutions.